Classification of Bricks

There are different types of bricks classified based on various categories. The categories of classification of bricks are as follows:

Classification of Bricks Based on Manufacturing Process

Extruded Brick

Extruded bricks are manufactured by pressing clay and water into steel die. Then, the resulting column is cut into shorter units before firing. It may contain 3 or 4 holes which constitutes 25% of volume of brick.

Moulded brick

Bricks that are moulded in to required shape and size are called as moulded bricks.These bricks are either hand moulded or machine moulded. Hand moulded bricks are extensively used in India. Hand moulding is further classified as Ground moulding or Table moulding depending on the area available for moulding.

Dry pressed Brick

These are the traditional bricks where clay is pressed into mould by applying high compression. Such bricks do not require drying and are fired directly. Dry pressed brick has deep frog on one surface & shallow frog on opposite surface. The quality of dry pressed brick is higher than extruded brick.

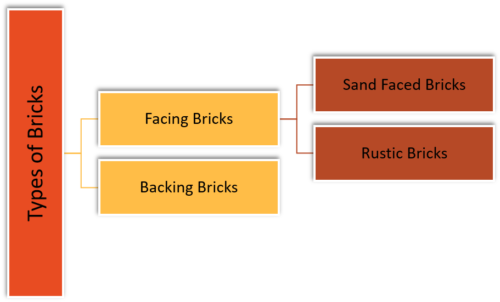

Classification of bricks Based on Using Location

Facing Brick

Bricks which can be used as façade material are classified as Facing Brick. Facing bricks come in varying textures. These bricks possess high durability. Facing bricks can be used on external walls of the buildings. Facing bricks are further classified as:

- Sand Faced Brick – Bricks obtained by sprinkling sand on inner surface of the mould, while manufacturing.

- Rustic Brick – Bricks of mechanically textured finish.

Backing Brick

The bricks placed behind facing brick are Backing Brick. These bricks act as support.

Classification of Bricks Based on Use

Common Bricks

Bricks which are economically manufactured bricks for general multipurpose are called as Common Bricks. These bricks do not require special consideration for appearance. Common Bricks are suitable for filling, backing and also for walls of unaesthetic nature.

Engineering Bricks

Engineering bricks are strong, impermeable, durable, acid resistant, damp proof and heat resistant. These brick must possess specific limits of water absorption and strength. Engineering Bricks are useful for constructing all load bearing structures, sewers, manholes, retaining walls and basements. Furthermore, Engineering bricks are classified into:

- Type A – These bricks have minimum compressive strength of 125 N/sq.mm & maximum water absorption of 4.5%

- Type B – These bricks have minimum compressive strength of 75 N/sq.mm & maximum water absorption of 7%

Classification of Bricks Based on Weather Resisting Capability

Severe Weather Brick

Such bricks are resistant to freeze thaw actions. Severe weather bricks are used in countries where it is completely covered in snow.

Moderate Weather brick

Moderate weather bricks can withstand high temperature. These bricks are more suitable for tropical countries.

No weather brick

These bricks do not possess any weather resisting capabilities. They are mostly used in internal walls.

Classification of Bricks Based on Shape

Bullnose Brick

Bullnose brick are bricks that possess rounded angle on one end.

Channel Brick

Channel bricks has the shape of the gutters. And hence, they are useful for constructing drains. These bricks are usually glazed. Also called as “Gutter Brick”.

Hollow Brick

The weight of hollow brick is about one third of the weight of normal brick. The reduction in weight is due to the provision of cavities. These bricks are mostly applicable for partitioning. Hollow bricks provide better insulation against heat and sound. Also called as “Cellular brick” or “Cavity brick”.

Cow Nose brick

Cownose bricks are bricks that has bullnose on both of its ends..

Paving brick

These bricks are used in garden park floors and pavements. It can withstand the abrasive action of traffic thus making the floor less slippery. Paving bricks are mechanically moulded and are not hand moulded.

Perforated brick

These bricks contain cylindrical holes. These blocks can be of different shapes like round, square, rectangular. Perforated bricks find its in the construction of the panels for lightweight structures, multistoried frames and are unsuitable for construction of hydraulic structures.

Coping brick

The brick provided at the top of parapet wall to provide coping to the wall is called as Coping brick. The shape of the brick can be chamfered, half rounded or saddle back.

Classification of Bricks Based on Raw Materials used

Concrete bricks

Concrete bricks uses concrete as raw material. These bricks can be manufactured at site. The requirement of mortar is less for concrete bricks. Concrete bricks possess good heat and sound insulation. They are suitable for the construction of façades, fence, masonry and framed structures. Concrete bricks come in different colors. The addition of pigments during manufacturing, results in variety of colors of bricks.

Fly ash Bricks

Fly ash bricks are Light weight, less porous and possess high weather resistant, high strength, high fire resistant, low water penetration. These bricks does not require soaking in water before using. The concentration of calcium oxide in fly ash is high. Hence, it is also called as “self-cementing bricks”. Fly ash bricks do not require plastering.

Sand lime bricks

Sand lime brick requires sand, lime and fly ash as raw material. The bricks are under pressure during moulding. And so, these bricks possess smooth finish and uniform shape. The color of sand lime bricks is Grey. They do not require plastering. They are suitable for ornamental works.

Fire Brick

Fire bricks are formed from specially designed earth. They can withstand high temperature. And so, they are suitable for the construction of lining of chimneys and furnaces.

Burnt Clay Bricks

These bricks are obtained by heating moulded clay in the kiln. Burnt clay bricks are more commonly used for construction. These bricks require plastering. For manufacturing of clay bricks – Click Here.

TYPES OF BURNT CLAY BRICKS

Clay bricks are classified into different types based on following categories:

Based on Burning

Unburnt Bricks

Unburnt bricks are dried under sunlight. Hence they are less durable and possess low strength, low water resistance and low fire resistance. Unburnt bricks are suitable for temporary structures. Unburnt bricks are not suitable for RCC footing or basement and as surkhi in lime terrace. Also called as “Sun dried bricks“.

Burnt Clay Bricks

These bricks are well burnt in kilns. Such bricks are of good quality. These bricks are further classified as First class bricks, second class bricks, third class bricks and fourth class bricks.

Over burnt brick

These bricks are fired at high temperature and for longer period. These bricks are in distorted shape and has high water absorption capacity. Over burnt bricks are suitable for coarse aggregate in concrete which does not come in contact with water. Also called as “Vitrified brick” or “Jhama brick”.

Based on IS 1077-1992

| Designation | Average Compressive Strength in N/mm2 |

|---|---|

| 35 | 35 |

| 30 | 30 |

| 25 | 25 |

| 20 | 20 |

| 17.5 | 17.5 |

| 15 | 15 |

| 12.5 | 12.5 |

| 10 | 10 |

| 7.5 | 7.5 |

| 5 | 5 |

| 3.5 | 3.5 |

Based on Field Practice

First Class Brick

The characteristics of first class bricks are:

- Bricks must be well burnt in large kilns.

- The color of the brick must be cherry, deep red or copper.

- The surface of the brick must be smooth and rectangular with parallel, sharp and straight edge and square corner.

- The brick must be free from flaws, cracks and organic matter and must have uniform texture.

- The finger nail must not leave any impression, when scratched on the surface of the brick.

- It produces a metallic ringing sound when two bricks strike against each other.

- Water absorption of bricks must lie between 10% and 12%.

- Crushing strength of brick must be greater than 10 N/mm2.

- Application – Pointing, exposed face work in masonry, flooring, reinforced brickwork.

- Suitable for permanent structure.

Second Class Brick

The characteristics of second class bricks are same as that of first class bricks except:

- Small cracks & distortions are permissible.

- The color of the brick is either uniform yellow or red.

- Crushing strength of brick must be greater than 7 N/mm2

- Water absorption of bricks must lie between 16% and 20%

- The surface of the brick is not smooth and the edges are also not sharp.

- Application – Masonry structure, centering of reinforced brick & RCC structure, one storied building.

Third Class Brick

The characteristics of third class bricks are:

- Bricks are under burnt, soft and light colored and of non-uniform texture.

- It produces a dull sound when two bricks strike against each other.

- Water absorption of brick can be up to 25%.

- Application – Temporary structures; not suitable for rainy areas.

- Bricks possess rough surface & unfair edges.

Fourth class Brick

The characteristics of fourth class bricks are:

- Overburnt.

- Badly distorted in shape & size.

- Brittle nature.

- Application – foundation, floor in lime concrete, aggregate in concrete.