Tests on Bricks

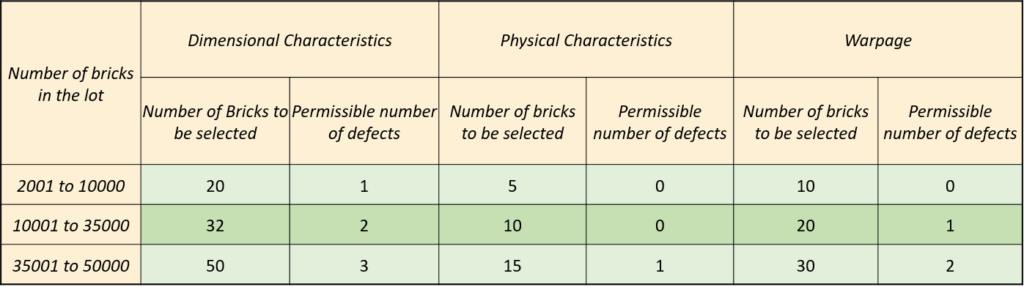

As a primary building material, the quality of the bricks must be analyzed before using for construction. It is determined by performing various tests on bricks. The tests for bricks are explained in IS 3495-1992 Part I to IV. In order to perform tests, select certain number of bricks from the available brick lot. The number of brick specimens required for testing are specified in IS 5454-1978 as explained below:

SAMPLING OF BRICKS

Sampling is the process by which predetermined number of specimens are selected for testing from a larger group of available specimens.

A lot is a collection of bricks of the same class and size, manufactured under relatively similar conditions of production. For the purpose of sampling, a lot shall contain a maximum of 50 000 bricks. If the number of bricks are more than 50,000 of same class and size and manufactured under similar conditions, then it is divided into groups of 50,000 or less.

The number of bricks to be considered for sampling is explained in IS 5454-1978 as follows:

Click Here to download IS 5454-1978

The various tests on brick that can be performed on site and laboratory are

DIMENSION TEST

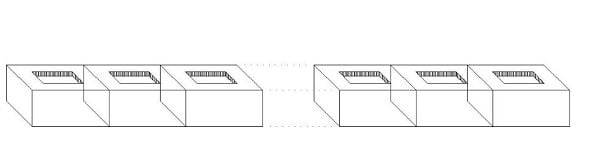

Dimension test is performed to determine the uniformity in the size of the bricks. Measure the length, width and height of the brick batch by laying flat 20 pieces of bricks as shown below:

Incase of modular bricks of size 190 mm x 90 mm x 90 mm, the tolerance permitted for 20 bricks as per IS 1077:1992 Clause 6.2.1 are as follows:

Length = 3800 ± 40 mm (190 x 20 = 3800)

Width = 1800 ± 20 mm (90 x 20 = 1800)

Height = 1800 ± 20 mm (90 x 20 = 1800)

If the measurements are outside the prescribed tolerance limits, then that particular lot of bricks is rejected to avoid the variation of perpends.

Click Here to download IS 1077-1992

COMPRESSION TEST

Compressive strength of brick represents the quality of brick and does not indicate the strength of masonry wall as the strength of masonry wall depends on the strength of mortar. Select the bricks at random. Measure the dimensions of the brick to the nearest 1 mm.

The compression test on brick is done as mentioned below:

- Step 1 – A brick is taken and the two parallel sides are made smooth. Then, immerse the brick in water for 24 hours. Take out the bricks from water. Wipe out the surface of the brick using a clean cloth.

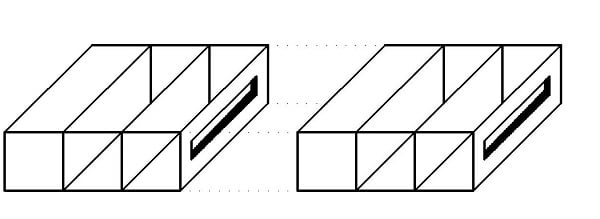

- Step 2 – Fill the frog with cement mortar. Now, place the bricks under damp jute bags for 24 hours. Then, place the bricks in water at room temp for about 3 days.

- Step 3 – Take out the bricks from water. Wipe the brick surface with a cloth.

- Step 4 – Place the specimen in Compression Testing Machine in such a way that the frog is at the top. Place two numbers of 3 mm thick plywood above and below the brick to apply uniform load on the specimen.

- Step 5 – Apply the loading at a constant rate of 14 N/mm2 per minute until failure.

- Step 6 – The maximum load at failure divided by the area of the bed face gives the compressive strength of brick.

If the compressive strength of any specimen falls below 20% of the minimum average compressive strength specified for that class of brick, then that particular test result is not considered. Minimum Compressive Strength of brick required to be used for construction is 3.5 N/mm2.

Click Here to download IS 3495-1992 Part I

WATER ABSORPTION TEST

Water absorption in brick is due to capillary action. It is an indication of degree of burning. Bricks of water absorption less than 7% will be less affected by frost. Water Absorption test on bricks is performed in two ways as follows:

24 hours immersion cold water test (IS 3495-1992 Part II)

- Step 1 – Dry the bricks in oven at 105°C to 115°C.

- Step 2 – Allow the oven dried bricks to cool. Note the weight of oven dried bricks as W1.

- Step 3 – Then, immerse the bricks in water at 27°C ± 2°C for a period of 24 hours.

- Step 4 – Take out the bricks from water and are surface dry them. Note the weight of surface dried bricks as W2.

5 hours boiling water test

- Step 1 – Dry the bricks in oven at 105°C to 115°C.

- Step 2 – Cool the oven dried bricks. Note the weight of oven dried bricks as W1.

- Step 3 – Immerse the specimen in water and boil the water for 5 hours.

- Step 4 – Allow the bricks to cool naturally to 27°C ± 2°C. It usually takes 16 to 19 hours. Note the weight of the bricks as W2.

The permissible water absorption for bricks is 20% when the compressive strength of brick is less than or equal to 12.5 N/mm2 and 15% when the compressive strength of brick is greater than 12.5 N/mm2

Click Here to download IS 3495-1992 Part II

EFFLORESCENCE TEST

The presence of soluble salts in brick earth causes efflorescence in bricks. Efflorescence test on bricks is done as mentioned below:

- Step 1 – Place the bricks in a porcelain or glass dish of 200mm diameter and 40 mm deep. Fill the dish with distilled water to a depth of 25 mm. Maintain the distilled water at room temperature (27°C ± 2°C).

- Step 2 – Place the brick in water until water gets absorbed by the brick or gets evaporated completely. Fill the water again up to a depth of 25mm and wait until the water disappears completely.

- Step 3 – Observe the deposit of efflorescence on the surface of the brick. The efflorescence is classified as:

- Nil – If the deposit of efflorescence is imperceptible.

- Slight – If the deposit of efflorescence covers less than 10% of exposed area of brick.

- Moderate – If the deposit of efflorescence covers 10% to 50% of exposed area of brick.

- Heavy – If the deposit of efflorescence covers more than 50% of exposed area of brick but the deposits do not flake away from brick surface.

- Serious – If the deposit of efflorescence covers more than 50% of exposed area of brick and the deposits flake away from brick surface.

The efflorescence in brick should not be more than moderate if the compressive strength of brick is less than or equal to 12.5 N/mm2 and should not be more than slight if the compressive strength of brick is greater than 12.5 N/mm2.

Click Here to download IS 3495-1992 Part III

FIELD TESTS ON BRICKS

It is not possible to always test the quality of bricks in laboratory. Sometimes, field tests come in handy in quick evaluation of the quality of bricks. Field tests are not accurate but these tests provide an approximate understanding on the properties of bricks. The various field tests that can be performed at site are listed below:

- The color of the brick must be uniform and it must be dark red or cherry colored.

- The shape of the brick must be rectangular with straight parallel faces and sharp edges.

- When dropped from a height of 1 m on hard ground, the brick should not break into pieces.

- The fractured surface of brick must not show any flaws, cracks or lumps.

- Scratch the surface of the brick with finger nail. It must not leave any impression on the surface of the brick.

- Soundness Test of Brick – Strike two bricks against each other. It must produce metallic ringing sound. It indicates the nature of brick against impact loads.

Thank you!!1

Thank you for the good writeup. It if truth be told used to be a leisure account it. Glance advanced to far delivered agreeable from you! By the way, how can we keep in touch?

Get in touch through gmail. Our mail id is civilunfoldian@gmail.com

You made some nice points there. I looked on the internet for the topic and found most people will go along with with your blog.

Thanks for the recognition.